SUSTAINABILITY

Product Carbon Footprint

Assessing your carbon emission quota and measuring your true carbon footprint is easy with carbon management services .......

Sustainable Solutions

Waetz Asia is committed to “Fashion without Compromise” and the expert services are delivered.....

ZLD/DAGAS-BIO

DAGAS BIO

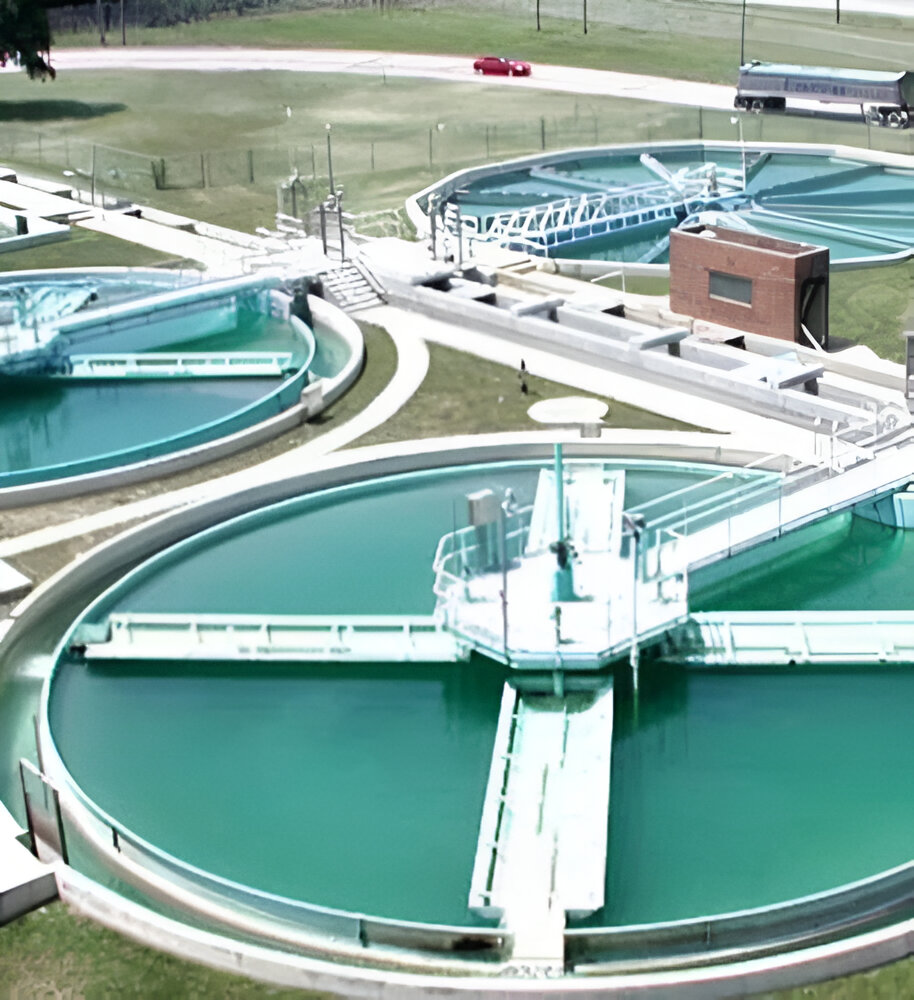

Biological Sewage Treatment Plant

The technology of DAGAS BIO uses the "biological conveyor" is based on biocenonosis and can be used in plants with a diversified business profile, e.g. municipal, chemical, oil processing, heavy metal, petrochemical, polygraphy, food, yeast, toxic, xenobiotic, pharmacy, etc.

How it Works?

The Biological Wastewater Treatment Plant in waetz asia consists of serially connected anaerobic, oxygen and anoxic bioreactors equipped with appropriate fibers carriers with large developed surfaces on which appropriate biocenoses are deposited. In the standard solution, there are initially three or more anaerobic bioreactors, followed by oxygen and anoxic bioreactors creating at least four pairs. There is a phytoreactor in the form of an uncovered water tank.

Advantages

- 10 x lower amount of waste produced in the purification process

- 4x smaller bioreactor capacity

- 4x smaller surface of the sewage treatment plant

- 5 x lower electricity consumption

- waste logistics costs minimized

- 4x lower costs of constructing a sewage treatment plant

- no active sludge recirculation, continuous one-way process

- use for all types of wastewater, including industrial, highly toxic with all organic substances dissolved in them including xenobiotics

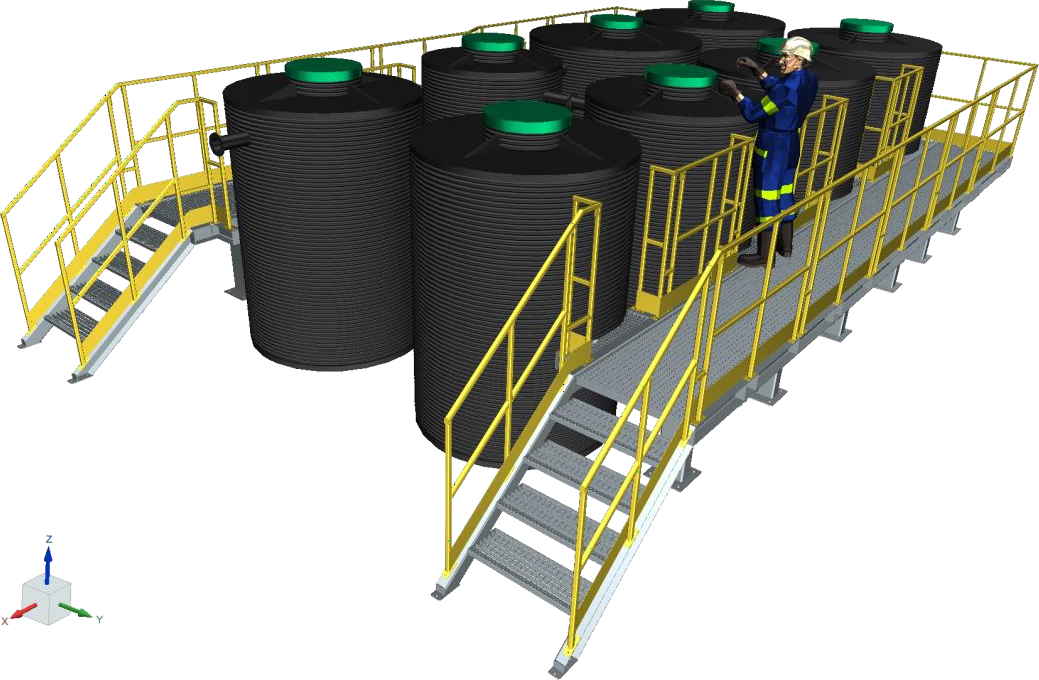

Zero Discharge Liquid

Our Zero liquid discharge system are to eliminate a liquid waste water discharge, generate solids for landfill disposal or reuse, and to recycle a high-quality water that can be beneficially reused.This means that so much water is extracted from the ecosystems, that there will be insufficient left to sustain them. Ultrafiltration and Reverse Osmosis Techniques are normally opted. Ultrafiltration is used to recycle flow or add value to later products and more. In many cases ultrafiltration (UF) is used for prefiltration in reverse-osmosis plants to protect the reverse-osmosis process. Ultrafiltration is an effective means of reducing the silt density index of water and removing particulates that can foul reverse osmosis membranes. Waetz asia By combining several processes, salt and purified water that can be reused in the technology, are recovered from the wastewater. This makes it possible to reduce the operating costs of the main technology. These benefits make ZLD one of the most popular technologies to reduce the industry's environmental impact.

How it Works?

Typically this treatment block consists of some type of clarifier and/or a reactor to precipitate out metals, hardness, and silica. Sometimes this step requires the addition of caustic soda or lime to help with coagulation, a process where various chemicals are added to a reaction tank to remove the bulk suspended solids and other various contaminants. This process starts off with an assortment of mixing reactors, typically one or two reactors that add specific chemicals to take out all the finer particles in the water by combining them into heavier particles that settle out. The most widely used coagulates are aluminum-based such as alum and polyaluminum chloride.